A magnetizer is specialized equipment that uses a powerful electrical pulse to permanently magnetize the components in an electric vehicle (EV) motor. This process fully aligns the magnetic domains within the magnets, ensuring optimal motor efficiency, torque, and consistent power output.

Frequently Asked Questions

What is a magnetizer and what does it do?

A magnetizer is specialized equipment that uses a powerful electrical pulse to permanently magnetize components in an electric vehicle (EV) motor. It works by generating an intense magnetic field that aligns all the microscopic magnetic domains within the material, transforming it into a powerful, permanent magnet.

How does proper magnetization improve an electric vehicle's performance?

High-quality magnetization directly improves an EV's performance by enhancing motor efficiency for better range, maximizing torque for instant acceleration and power, and ensuring consistent, reliable performance by eliminating variations, vibrations, and noise.

Why are capacitive discharge magnetizers necessary for EV motors?

EV motors use high-performance rare earth magnets with high coercivity (resistance to demagnetization). Simpler methods like DC electromagnets lack the strength to fully saturate these materials. Capacitive discharge magnetizers are the industry standard because they can store and release a massive amount of energy in a single, powerful pulse, creating the intense magnetic field required to fully activate the magnets.

What is the role of a magnetizing fixture?

While the magnetizer provides the power, a magnetizing fixture provides the precision. It is a custom-engineered tool that holds the motor component and shapes the magnetic field during the pulse. This ensures that the complex pattern of north and south poles required for the motor to function correctly is applied to the exact locations needed.

How Does a Magnetizer Work? The Physics of Magnetization

To understand how a magnetizer works, think of an unmagnetized permanent magnet: internally, it’s made up of countless microscopic regions called magnetic domains. Before magnetization, these domains are not aligned in a functional direction, but the reason why differs by magnet type:

- Bonded NdFeB magnets are isotropic, meaning their domains have no preferred magnetic axis after molding. They can be magnetized into various multipole patterns, depending on the application.

- Sintered NdFeB magnets, on the other hand, are anisotropic. During pressing, the material is aligned into a preferred magnetic orientation. This manufacturing step gives sintered magnets their higher performance but limits the available pole patterns.

Regardless of type, a magnetizer’s job is to apply a very strong, short magnetic pulse—often 3 to 5 Tesla—to fully activate the magnet’s performance. High-coercivity NdFeB (common in EV motors) requires especially powerful magnetizers to achieve full alignment and stability.

This process is especially critical for the high-performance rare earth magnets, such as Neodymium (NdFeB), used in modern EV motors. Their high coercivity makes them resistant to demagnetization but also requires a very powerful magnetizer to fully activate them.

The Critical Role of Magnetizers in EV Motor Performance

The quality of magnetization has a direct and significant impact on an EV's performance. Simply put, a poorly or incompletely magnetized motor is an underperforming motor. Here’s why the process is so crucial:

Enhanced Motor Efficiency

A uniformly and fully magnetized rotor creates a stronger, more consistent magnetic field. This allows the motor to convert electrical energy into rotational force with minimal waste. The result is better vehicle range and less energy consumption.

Maximum Torque and Power Output

The torque—or rotational force—of an EV motor is directly proportional to the strength of its magnetic fields. By using a high-quality system like the Magnetizer to achieve full magnetic saturation, manufacturers ensure their motors deliver the instant acceleration and peak power that drivers expect.

Consistent and Reliable Performance

Inconsistent magnetization can lead to performance variations, unwanted vibrations, and noise. A precise magnetization process guarantees that every motor coming off the production line performs exactly as designed, ensuring a smooth, reliable driving experience.

Choosing the Right Technology: Not All Magnetizers Are Created Equal

For a demanding application like an EV motor, the type of magnetizer used is non-negotiable. The technology must be capable of saturating high-coercivity rare earth magnets.

The Industry Standard: Capacitive Discharge Magnetizers

This technology is the gold standard for high-energy applications. A capacitive discharge magnetizer stores a massive amount of electrical energy and releases it in a single, powerful pulse through a coil. This creates the intense magnetic field necessary to activate high-performance magnets.

Advanced industrial systems, such as the Magnetizer developed by Magnet Applications, are built on this principle. They are specifically engineered to provide the power and control needed to magnetize complex components like EV rotors.

Why Other Methods Fall Short for EVs

- DC Electromagnets: These systems lack the field strength required to fully saturate rare earth magnets. Using one would result in a significantly weaker, underperforming motor.

- Permanent Magnet Magnetizers: While useful for some applications, they are not powerful enough and lack the flexibility needed for the complex, multi-pole magnetization patterns required in advanced EV motors.

Precision is Key: The Role of Custom Magnetizing Fixtures

Power is only half the equation; precision is the other. An EV motor rotor isn’t a simple bar magnet. It requires a complex pattern of north and south poles to function correctly. This is where a magnetizing fixture comes in.

A custom fixture is a precisely engineered tool that holds the motor component and shapes the magnetic field during the pulse. It ensures that the magnetic energy is applied to the exact locations needed to create the specified multi-pole configuration.

A comprehensive solution like the Magnetizer is always paired with custom-designed fixtures. Because Magnet Applications designs and builds both the systems and the fixtures in-house, they guarantee a perfect synergy between power and precision, ensuring flawless magnetization every time.

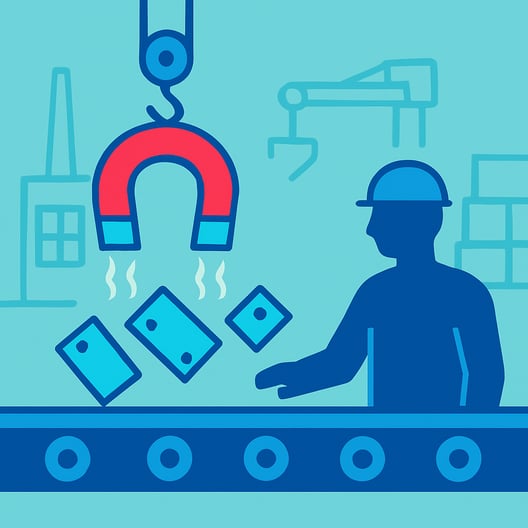

The Magnetizer Advantage in Production Environments

In a high-volume manufacturing setting like an automotive plant, a magnetizer must be more than just powerful—it must be a reliable, integrated part of the production line. The Magnetizer is designed for this reality, offering several key benefits:

- Seamless Production Line Integration: With PLC (Programmable Logic Controller) controls, the Magnetizer can be fully automated, integrating directly into an existing assembly line for maximum efficiency.

- Optimized for EV Materials: These systems are engineered specifically for bonded NdFeB and other rare earth magnets common in the automotive and aerospace industries.

- Guaranteed Performance: By controlling the design of both the machine and the fixtures, the process guarantees consistent, repeatable results, eliminating performance variability.

- Support for Complex Geometries: Whether it's a simple 2-pole motor or a complex multi-pole traction motor, the system is configured to handle the precise requirements of the design.

Conclusion: Why the Right Magnetization Process is Non-Negotiable

The hidden power behind every high-performance electric vehicle motor isn't just the magnet itself—it's the quality of the magnetization process that unlocked its potential. A magnetizer is the critical tool that transforms a piece of inert material into the heart of an efficient, powerful, and reliable motor. For manufacturers seeking to deliver top-tier performance, investing in a production-ready, high-field system like the Magnetizer isn't just an option; it's essential.