Melt Spun/Jet Milled Isotropic Bonded Magnets

By Dr. John Ormerod

Technical Adviser / Bunting-DuBois

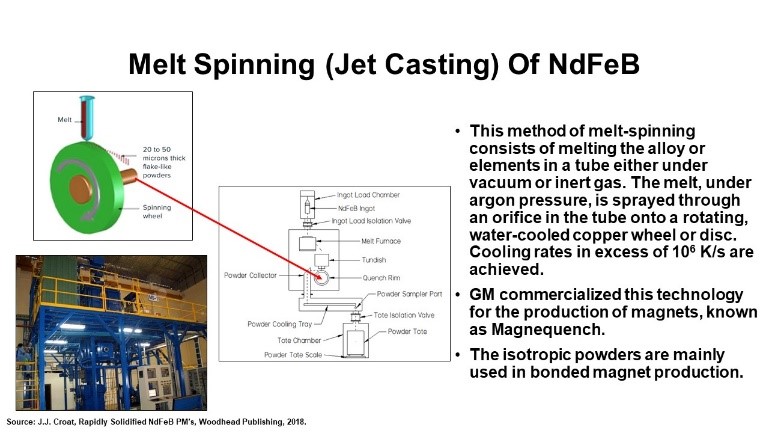

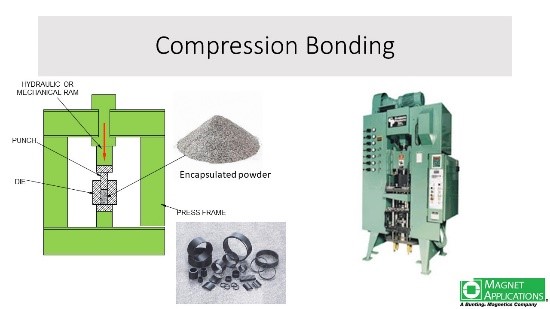

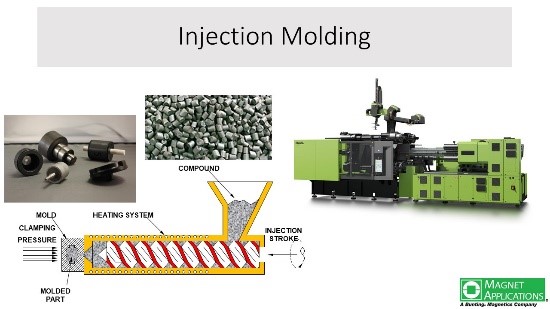

In the early 1980’s, General Motors Corporation (later Magnequench) pioneered the use of melt spinning to produce an isotropic NdFeB powder which is used primarily in bonded magnet production; either compression bonding or injection molding as shown below.

The principle of melt-spinning consists of melting the alloy or elements in a tube under vacuum or inert gas. The melt, under inert gas pressure, is sprayed through an orifice in the tube onto a rotating, water-cooled copper wheel or disc. Cooling rates in excess of 1,000,000 C/sec. are achieved which produces an alloy with an amorphous or fine grained nanocrystalline structure.