Magnet Material Selection

Manufactured in DuBois, Pennsylvania, Bunting is the only North American manufacturer of compression bonded, injection molded and hybrid magnets. In addition, we provide a complete range of permanent magnet types including sintered neodymium magnets and magnetic assemblies. Our exclusive NeoBlend™ neodymium magnets can be designed to any size, shape or strength thanks to a complete range of presses from 4-ton to 200-ton.

Bunting engineers are ready to assist you with the important task of magnet material selection. Our material selection includes the full range of NdFeB grades including radial rings and the latest high temperature grades for the most demanding applications. The design considerations include thermal properties, mechanical properties, cost, energy product, oxidation, electrical conductivity and more. Read more about Permanent Magnets in our Tech Brief here.

Permanent Magnets

Permanent magnets are essential to virtually every type of modern technology and convenience. Being able to provide the optimum magnetic solution to the customer requires in-depth knowledge of the full supply chain. Bunting’s team of magnet experts and engineers is fully equipped with this knowledge. Bunting entered the magnetics industry in 1959 as a magnet distributor and rapidly grew to a manufacturer of magnetic products, focused on custom design and customer-focused engineering. Today, Bunting is a leader in manufacturing and designing a diverse range of innovative magnetic technologies across industry sectors. Listed below are the general permanent magnet types that are used in Bunting products.

Ceramic Magnets

- Produced from Barium or Strontium ferrite powders

- Excellent choice for low cost and low Br requirements – up to 4.2 MGOe

- Corrosion-resistant

- Ideal for use in electrical insulators

- Withstands high temperature environments – up to 300°C

Ceramic magnets, or ferrite magnets, are low cost, lightweight, moderate energy permanent magnets capable of withstanding operating temperatures of up to 480°F. They are highly corrosion resistant and work well in high volume applications. These qualities make them a popular choice in manufacturing and consumer applications such as speaker magnets, DC motors, reed switches, sweepers, MRIs, and automotive sensors.

The most popular grades of ceramic magnet are 5 and 8. These are anisotropic grades, which are considered the most powerful. Anisotropic magnets experience magnetization exclusively in the direction formed during the pressing operation, resulting in a magnet with an overall magnetic flux output. Ceramic magnets can be made in many shapes and sizes, can be ground to intricate and accurate shapes, and can even be designed to be small enough to be used in micro applications.

Alnico Magnets

- Made from Aluminum, Nickel and Cobalt

- Available up to 5.5 MGOe; easily demagnetized

- Corrosion-resistant

- Ideal for use in electrical insulators

- Maximum high temp resistance – up to 540°C

Alnico magnets are alloys comprised of aluminum, nickel, iron, and cobalt. They have the highest operating temperature and temperature stability of any permanent magnetic material. They retain approximately 85% of room-temperature magnetization at temperatures of up to 1,000°F. They possess high residual induction as well as relatively high energy products. Alnico magnets naturally possess an excellent corrosion resistance. This makes surface treatment unnecessary, although they may still be easily plated if desired. Alnico magnets may be produced by either casting or sintering.

Cast alnico magnets are manufactured by pouring a molten metal alloy into a mold and processing it through various heat-treat cycles. Cast magnets may be manufactured in complex shapes, which is difficult to achieve with other magnet materials. They can function as very powerful magnets and are ideal for applications where fine tuning is advantageous.

Types of Cast Alnico:

• Cast Alnico 5, the most common alnico magnet, is used extensively in rotating machinery, meters, instruments, sensing devices, and holding applications. For best results with alnico 5 magnets, the length should be no less than 5 times the cross-section diameter, or 5 times the diameter of a circle equal in area to the cross section.

• Cast Alnico 8 HE has the highest temperature stability of any commercially available magnetic material. Improved crystal structure and alloying techniques achieve a high maximum energy product and higher resistance to demagnetization. Typical uses include computer keyboards, drives, printers, microphones, meters, motors, generators, relays, reed-switch relays, and transducers.

Sintered alnico magnets are manufactured by compacting fine alnico powder in a press, then sintering the compacted powder into a solid magnet. Compared to cast alnico, sintered alnico has marginally lower magnetic properties but overall better mechanical properties. Sintered alnico 8H has a high temperature stability, coercivity, and demagnetization resistance similar to Cast alnico 8, but it can be manufactured to closer tolerances. The fine grain structure of alnico magnets results in highly uniform flux distribution and mechanical strength, so they are an excellent fit for applications requiring short magnetic length or involving high-speed motion. Some applications include core meters, traveling wave tube stacks, polarized relays, reed switches, torque transmitting devices, and sandwich-type holding assemblies.

Alnico Magnet Material Charts

Samarium Cobalt Magnets

- Rare Earth magnet

- Extremely strong – currently up to 32 MGOe

- Less susceptible to oxidization and more brittle than Neodymium

- Withstands high temperature environments – up to 300°C

- Generally more expensive than Neodymium

Samarium cobalt magnets are rare earth magnets that offer high maximum energy products and can operate in high temperature environments. They are extremely strong and typically allow for smaller size magnet profiles. Though not as strong as neodymium magnets, samarium cobalt magnets present three significant advantages. They work over a wider temperature range, have superior temperature coefficients, and also have a greater resistance to corrosion. Special coatings are available for specific marine and automotive applications.

Since samarium cobalt offers excellent corrosion resistance, these magnets typically do not require a surface treatment. They also have good resistance to external demagnetizing fields because of their high intrinsic coercive force (Hci). This resistance makes samarium cobalt rare earth magnets an excellent choice for demanding motor applications. They are available in three grades up to 32 MGOe.

Samarium cobalt magnets are one of the most useful magnets for high temperature applications. They retain most of their energy up to 575° F, making them ideal replacements for Alnico magnets when high temperature use or miniaturization is required. Samarium cobalt magnets are known for their excellent temperature stability—maximum use temperatures are between 250 and 550°F; Curie temperatures range from 700 to 800°F.

Samarium Magnet Material Charts

High Temperatures and Neodymium Magnets

Like other rare earth magnets, neodymium magnets have a high resistance to demagnetization. They will not lose their magnetization if dropped or exposed to other magnets. However, neodymium magnets will completely lose their magnetization if heated above their Curie temperature, which is 590°F (310°C) for standard N grades.

Neodymium magnets are available for standard temperature and high-temperature applications. Standard temperature neodymium magnets will begin to lose strength if they are heated above their maximum operating temperature, which is 180°F (80°C). High-temperature neodymium magnets can safely be used at operating temperatures up to 300° F (149° C). Special grades are also available that can operate in excess of 392°F (200°C).

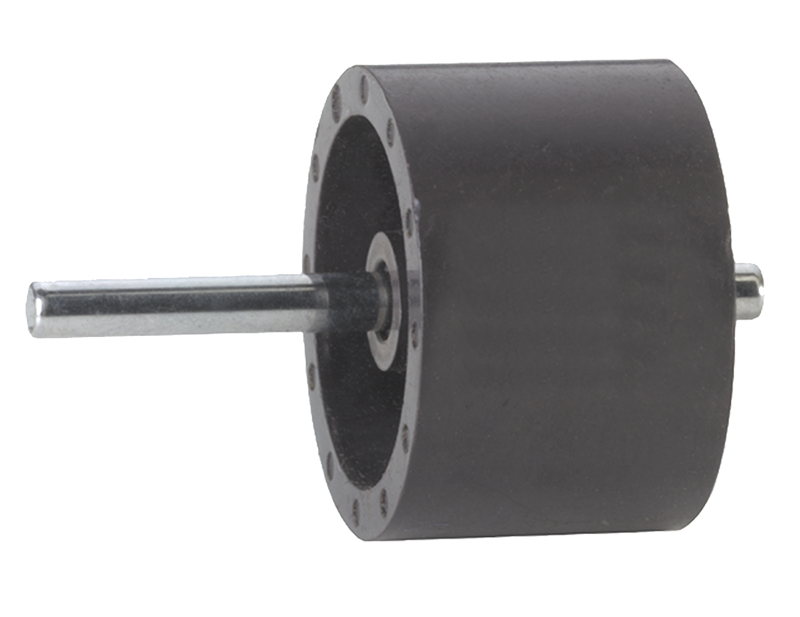

Neodymium Iron Boron Magnets

- Rare Earth magnet

- Offers the highest Br and Hci values

- The strongest magnet available – up to 52 MGOe

- Susceptible to oxidation due to high iron content

- Can be used in environments up to 200°C

Neodymium magnets are a type of rare earth magnet and are the most common rare earth permanent magnets in the world. They are composed of Neodymium (Nd), Iron (Fe) and Boron (B), and exhibit the highest maximum energy product of any permanent magnet material. However, these magnets are vulnerable to corrosion if they are exposed to the elements. To protect the magnet from corrosion, the magnet is usually coated with nickel. Other coating options are aluminum, zinc, tin, copper, epoxy, silver and gold.

Extremely strong and affordable, neodymium magnets are commonly used in consumer products such cell phones, loudspeakers, fasteners and toys. Industrially, they are used in metal detectors, oil filters, alternators, flow meters and as clamps by welders. MRI machines, hybrid and electric vehicles, and wind turbines all employ neodymium magnets.

These high power magnets achieve maximum performance while maintaining minimum size.

Can be made in blocks, rings, arcs, discs, spheres, trapezoids, triangles, and many other shapes.

Ni-Cu-Ni plating is most commonly applied, other coatings/finishes available.

Radially aligned magnets are available to replace arcs.

Grain boundary diffusion is now available in commercial quantities.

Neodymium Magnet Material Charts

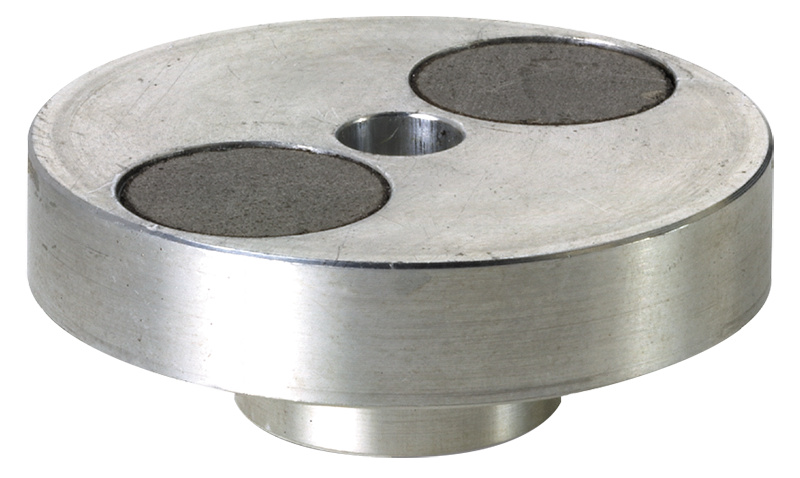

Plastic Bonded Neodymium Magnets

- Popular resin bonded magnet (resin bonds particles during the compression bonded or injection molded process)

- Available up to 12 MGOe and with a coating

- Typical applications include encoders and BLDC motors

- Temperature limit of 150°C

- Low cost, low electrical conductivity

These magnets are-cost effective while offering high performance and tolerances in addition to low electrical conductivity. It is possible to multipole magnetize them as a complete ring, and they can be designed to achieve specific flux density profiles. These are especially well suited for applications such as minimizing cogging torque in motors. These injection molded magnets are an excellent choice for higher volume applications. Compression bonded magnets can also be easily machined, making them suitable for low volume production in manufacturing magnets with multipole magnetization, skew angled poles, and various other directions of magnetizations. Magnetizing patterns are only limited by whether or not a magnetizing coil fixture can be produced to give the required magnetizing pattern.

- Bonded NdFeB magnets can be compression or injection molded to net shape. These high tolerances can be achieved without the need for further machining.

- Injection molded magnets are available in both neodymium and ferrite varieties.

- Injection molded ferrite magnets offer high durability and resistance to shock, as well as a low cost and extreme resistance to corrosions and conditions such as low density.

- Available in high tolerance and complex shapes.

- No coating required, although black epoxy and Parylene coatings are available.

Bonded Neodymium Magnet Material Charts

RoHS Compliance

Bunting® ensures that we have restricted the use of certain hazardous substances (RoHS), namely lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and polybrominated diphenyl ethers. Our stock magnets meet or exceed Magnetic Materials Producers Association Standards for physical quality and magnetic properties.

All permanent magnet products are ROHS and REACH compliant, as well as free of SVHCs.

Manufactured at ISO9001, ISO140001, and TS16949 accredited, audited partners.

Certificates of conformity, MSDS, and PPAPs are available.

What You Can Expect From Bunting:

• 2D and 3D magnetic modeling of your design

• Rapid prototyping of designs

• Capacity to manufacture magnets and magnetic assemblies in any quantity

• Extensive quality checks of product

• On-time delivery

At Bunting, we engineer a custom magnet to fit your specific needs. We combine ingenuity, our deep expertise, and our dedicated range of equipment in order to deliver you the exact product you need with no sacrifice to quality design and engineering.

Talk to one of our magnet experts today. Contact us here.